Content

Water Supply Treatment

Update: 30/11/2024

Share:

What is a Raw Water Treatment System?

A raw water treatment system is a crucial part of many industries, ranging from food production to pharmaceuticals and electronics. Water treatment ensures that the water quality meets the required standards, protects consumer health, and maintains stable production operations. So, what equipment does this system include? Let’s explore in the article below.

Sedimentation Tanks and Filtration Tanks

Sedimentation tanks and filtration tanks are the first two important components of the raw water treatment system. The sedimentation tank helps remove larger particles and suspended solids from the water through the natural process of sedimentation.

Afterward, the water is transferred to the filtration tank, where smaller particles and remaining impurities are removed. Filtration tanks typically use layers of filter materials such as sand, activated carbon, or other special materials to ensure high filtration performance.

Disinfection System

After the water has been sedimented and filtered, the next step is disinfection to eliminate bacteria, viruses, and harmful microorganisms. Disinfection systems can use various methods such as UV lights, ozone, or chemicals like chlorine.

UV lights and ozone are methods that leave no chemical residue and are commonly used in industries with high safety requirements, such as food production and pharmaceuticals.

RO (Reverse Osmosis) System

The Reverse Osmosis (RO) system is one of the most advanced technologies in water treatment. RO uses a special membrane to remove most ions, molecules, and even the smallest impurities remaining in the water. RO systems are typically used when high-purity water is needed, such as in pharmaceuticals production, electronics, or bottled drinking water.

Water Softening System

The water softening system is an essential part of treating hard water, which contains high levels of calcium and magnesium ions. This equipment uses ion exchange resins to remove calcium and magnesium ions, replacing them with sodium or potassium ions. The water softening system helps protect equipment and pipes in the water treatment system from scaling, extends their lifespan, and improves operational efficiency.

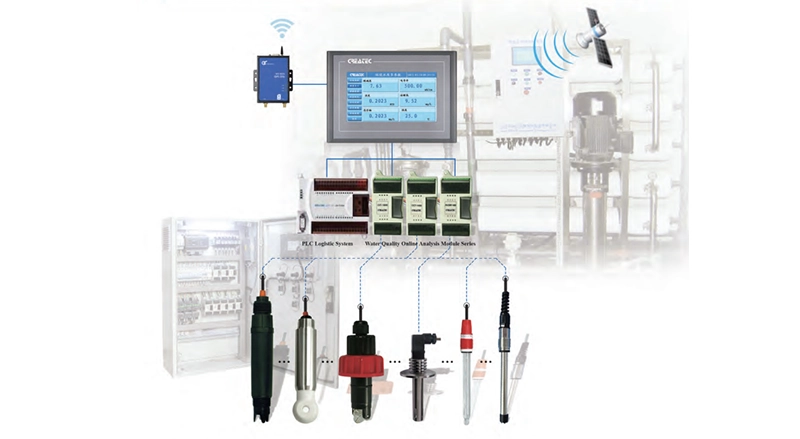

Water Quality Control System

To ensure the water meets the required standards, a water quality control system is indispensable. This system includes devices that measure and monitor water quality indicators such as pH, hardness, chlorine content, and other pollutants. Data from these measuring devices help technicians adjust the water treatment process accurately and efficiently.

The water treatment system for production involves various modern equipment and technologies to ensure the water quality meets the standards. From sedimentation and filtration tanks, disinfection systems, RO systems, to water softening and water quality control, each component plays a crucial role in providing clean and safe water for the production process.

Current Water Treatment Technology

Water treatment technology involves applying advanced, modern processes with various stages and levels aimed at removing dirt and harmful substances. This helps improve the quality of the water, making it safer for both domestic and industrial use.

Role and Purpose

The main role and purpose of surface water treatment technology include:

- Eliminate heavy metals and high-valency metals present in the water such as iron and manganese (from riverbed and lake water sources).

- Balance the mineral content in the water by reducing cation metals like calcium and magnesium to permissible levels (depending on soil quality and rainfall). This helps reduce water hardness.

- Remove microorganisms present in the water to ensure the water becomes safe for human health.

- Filter out dirt, debris, and impurities mixed in the water, making the water cleaner and clearer.

- Remove organic substances found in the water source.

Outstanding Features

Surface water treatment technology has the following outstanding features:

- Intelligent, modern systems that are easy to use and maintain.

- Components imported from advanced countries, ensuring high and stable operational capacity.

- This water treatment technology is suitable for large-scale facilities that require large volumes of water.

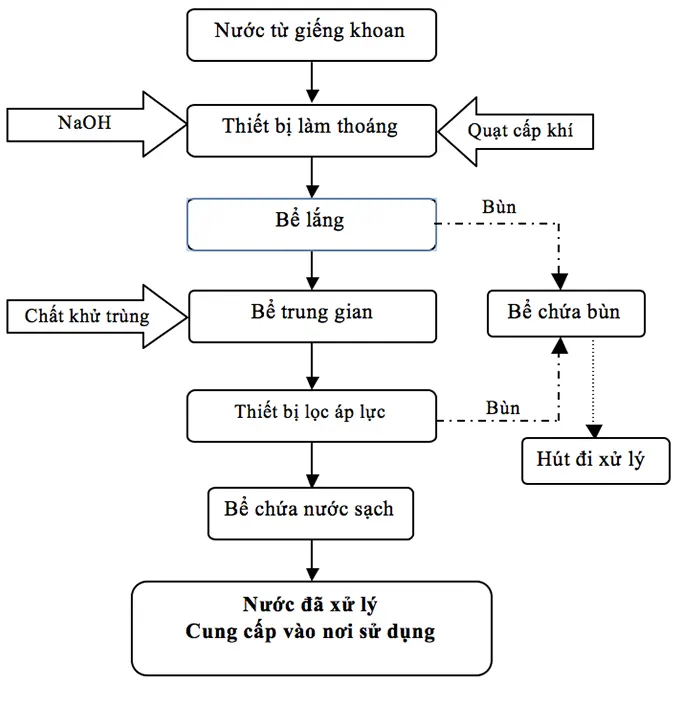

Water Treatment Technology Diagram

The most effective water treatment process from surface water sources worldwide includes the following basic steps:

Detailed Domestic Water Treatment Process

Pre-treatment

Pre-treatment is commonly applied in global water treatment technology due to its significant role. The main purpose is to remove large impurities and waste from the water source. This process not only cleans the water but also helps prevent clogging in subsequent water treatment systems. The surface water pre-treatment stage includes the following steps:

- Trash racks and mesh screens remove waste, floating plants, algae, and debris from the water.

- Settling tanks: Surface water usually has high turbidity due to the presence of sand, silt, and suspended impurities.

Therefore, the water is passed into the settling tank, where it remains for a certain period to allow the impurities to settle at the bottom. The sludge at the bottom is periodically removed and pressed into dry sludge cakes, which are then disposed of.

Chemical Treatment

Chemical treatment at this stage is primarily aimed at removing algae and plankton that are abundant in surface water. It also kills microorganisms and harmful substances caused by contamination from domestic wastewater, factories, and industrial zones.

Chemical water treatment process helps prevent waste and debris from entering the treatment system, thereby protecting the equipment within the system.

Using Coagulant Aid to Form Flocs

Coagulant aid chemicals help bind small suspended particles or impurities in the water into larger sludge flocs. This makes it easier to remove these impurities from the water.

This is a crucial step in the surface water treatment diagram, as it significantly contributes to improving the clarity and cleanliness of the water source.

Sedimentation Process

After coagulation, large particles will settle at the tank using the following support methods:

- Gravity sedimentation of sludge flocs.

- Centrifugal sedimentation in the tank.

- Using flotation forces acting on air bubbles attached to the particles.

Filtration Process

The main goal of this process is to retain large suspended particles, as well as colloidal iron and organic colloids that cause water turbidity and discoloration.

Large particles are easily blocked by the filter membrane. Even smaller particles than the filter’s pore size are still easily retained as they are absorbed and bound to the filter media surface.

Disinfection Process

This is a critical stage in surface water treatment, as it kills up to 99.9% of viruses and bacteria that could harm human health.

Currently, there are three main disinfection methods used in the surface water treatment process:

- Chlorine disinfection.

- Ozone injection disinfection.

- UV light disinfection.

Bacterial Removal Process

Afterwards, it’s necessary to filter out the dead bacteria to avoid their decomposition, which could cause unpleasant odors in the water.

.webp)

Once the bacteria are removed, the surface water becomes clean and meets the required standards. It can then be used for domestic purposes and production as usual.

Modern Water Treatment Companies in Vietnam

Toàn Á - A Leading Company You Shouldn’t Miss

Toàn Á is a water treatment company with nearly 20 years of experience in the water industry. We have successfully consulted, designed, and installed systems and projects for thousands of businesses of all sizes across the country.

Advantages of Using Surface Water Treatment Technology at Toàn Á JSC

- The surface water source after treatment meets the standards for drinking and production water quality.

- Low operating costs, with industrial water filter maintenance being reduced due to imported equipment, which ensures high durability and stability.

- Simple operation, easy to manage and use, saving time and effort for personnel.

- High filtration capacity, capable of meeting large surface water filtration needs.

- Minimal space required for building settling tanks with no sludge overflowing into the clean water tank.

Overall, this surface water treatment technology is currently widely applied. If you have any needs, feel free to contact us via our hotline: 0913.543.469 for expert assistance.

Update: 30/11/2024

Share:

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News